Design Assistance - Sizing Suggestions

Sizing a Pipe System

DUCT INCORPORATED offers assistance for those who need help designing a piping system. We can help determine the correct pipe size and configuration that will supply the flow you need. Please contact us at 1 877-BUY-DUCT for assistance.

USING THE CFM/FPM CHART:

The following chart allows you to pick the correct pipe for the required CFM.

To prevent waste material from dropping out of the air stream, each type of material needs to be conveyed at different velocities. (See table on page 28.) For example, some waste materials flow well at 4500 feet per minute (FPM). Reviewing the chart, a 4” pipe will convey 395 CFM at 4500 FPM. This means that a 4” pick-up on a machine will use 395 CFM from the filtering system; or, if you know that a machine will require approximately 400 CFM to remove the waste, you should use a 4” pipe for that purpose.

|

Air Volume in Ducts in Cubic Feet per Minute (CFM)

|

|||||||||||

|

2000

|

2500

|

3000

|

3500

|

4000

|

4500

|

5000

|

5500

|

6000

|

6500

|

7000

|

|

|

3

|

100

|

125

|

150

|

170

|

195

|

220

|

245

|

270

|

295

|

320

|

345

|

|

4

|

175

|

220

|

260

|

305

|

350

|

395

|

440

|

485

|

525

|

570

|

615

|

|

5

|

275

|

340

|

410

|

475

|

545

|

615

|

680

|

750

|

820

|

885

|

955

|

|

6

|

395

|

490

|

590

|

685

|

785

|

885

|

980

|

1080

|

1180

|

1275

|

1375

|

|

7

|

535

|

670

|

800

|

935

|

1070

|

1205

|

1335

|

1470

|

1605

|

1735

|

1870

|

|

8

|

700

|

875

|

1050

|

1220

|

1395

|

1570

|

1745

|

1920

|

2095

|

2270

|

2445

|

|

9

|

885

|

1105

|

1325

|

1545

|

1765

|

1990

|

2210

|

2430

|

2650

|

2870

|

3090

|

|

10

|

1090

|

1365

|

1635

|

1910

|

2180

|

2455

|

2725

|

3000

|

3270

|

3545

|

3820

|

|

12

|

1570

|

1965

|

2355

|

2750

|

3140

|

3535

|

3925

|

4320

|

4710

|

5105

|

5500

|

|

14

|

2140

|

2675

|

3205

|

3740

|

4275

|

4810

|

5345

|

5880

|

6415

|

6950

|

7485

|

|

16

|

2790

|

3490

|

4190

|

4885

|

5585

|

6285

|

6980

|

7680

|

8380

|

9075

|

9775

|

|

18

|

3535

|

4420

|

5300

|

6185

|

7070

|

7950

|

8835

|

9720

|

10600

|

11485

|

12370

|

|

20

|

4635

|

5455

|

6545

|

7635

|

8725

|

9815

|

10910

|

12000

|

13090

|

14180

|

15270

|

|

22

|

5280

|

6600

|

7920

|

9240

|

10560

|

11880

|

13200

|

14520

|

15840

|

17160

|

18480

|

|

24

|

6285

|

7855

|

9425

|

10995

|

12656

|

14135

|

15710

|

17280

|

18850

|

20420

|

21995

|

|

26

|

7370

|

9210

|

11055

|

12900

|

14740

|

16580

|

18420

|

20270

|

22110

|

23950

|

25800

|

|

28

|

8550

|

10685

|

12820

|

14960

|

17100

|

19230

|

21310

|

23500

|

25650

|

27780

|

29920

|

|

30

|

9800

|

12260

|

14700

|

17170

|

19625

|

22080

|

24530

|

26990

|

29440

|

31890

|

34350

|

|

32

|

11160

|

13950

|

16750

|

19541

|

22330

|

25120

|

279120

|

30700

|

33490

|

36380

|

39070

|

Sizing Branches

Example:

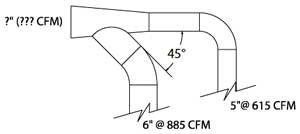

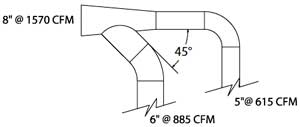

When working from your machines back toward the filter, you have a 5” drop that rises and joins with a 6” drop (see diagram below). How do you figure what size branch you’ll need?

The 5” pipe carries 615 CFM at 4500 FPM (see chart above). The 6” pipe needs 885 CFM at the same velocity of 4500 FPM. Added together, there is a total of (615 + 885) 1500 CFM coming together.

Referring back to the chart under the 4500 CFM column, 1500 CFM is not listed, but is close to the 1570 CFM listed for an 8” pipe. This states that the 5” joined with the 6” requires an 8” pipe to carry the combined material at the correct velocity. The branch will need to be 8” on the downstream end reducing down to a 5” with a 6” branching off of it. This would be listed as an 8-5-6 branch.

|

|

Example: When working from your machines back toward the filter, you have a 5” drop that rises and joins with a 6” drop (see diagram below). How do you figure what size branch you’ll need? he 5” pipe carries 615 CFM at 4500 FPM (see chart above). The 6” pipe needs 885 CFM at the same velocity of 4500 FPM. Added together, there is a total of (615 + 885) 1500 CFM coming together. |

|

Referring back to the chart under the 4500 CFM column, 1500 CFM is not listed, but is close to the 1570 CFM listed for an 8” pipe. This states that the 5” joined with the 6” requires an 8” pipe to carry the combined material at the correct velocity. The branch will need to be 8” on the downstream end reducing down to a 5” with a 6” branching off of it. This would be listed as an 8-5-6 branch.

|